Chain Disk Conveyors

Chain disk conveyors are a flexible and reliable solution for moving malt and grist through brewing and distilling facilities. Their gentle conveying action helps preserve grist integrity and maintain consistent milling performance.

These systems are well suited for long distances, multiple direction changes, and complex routing where other conveyor types struggle. Available in multiple diameters with a range of control and material options, chain disk conveyors provide durable performance and strong value across a wide range of applications.

Flex Augers

Flex augers are an economical option for simple conveying routes, particularly upstream of the mill. Using enclosed tubing helps reduce dust, limit contamination, and lower noise levels while allowing for modest routing flexibility.

Available in diameters from approximately 2.2 inches up to 5 inches, flex augers can support a wide range of production capacities. Galvanized and rigid auger options are also available where additional durability or structural support is required.

Bucket Elevators

Bucket elevators are a traditional solution for high-capacity vertical conveying of grain and other granular materials. They are most commonly used in mechanically fed systems where grain is received from a pit, hopper, or screw or belt conveyor and then elevated for distribution to one or more bins or silos.

For many brewery and distillery projects, pneumatic silo filling is often the simplest approach. Bucket elevators are typically considered when a site calls for a fully mechanical receiving and conveying layout, when very high throughput is required, or when an operation is standardizing around grain-industry equipment and workflows.

Spent Grain Removal

Handling spent grain efficiently is just as important as moving dry malt. Even smaller operations can benefit from systems that reduce manual handling, improve sanitation, and simplify disposal.

Options include conveying systems, pumps, and storage bins designed specifically for spent grain. Elevated bins with drive-through access allow material to be discharged directly into trailers, while ground-mounted systems can be paired with pumps for controlled removal.

Systems can be configured with heating, insulation, stainless or powder-coated construction, and a variety of discharge options to suit climate, layout, and hauling requirements.

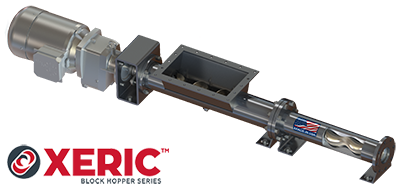

Progressive Cavity Pumps

Progressive cavity pumps are commonly used for spent grain and slurry handling due to their steady flow, dry-run capability, and compact footprint. We frequently specify pumps such as the Xeric Black Hopper Series from Roper Pumps.

These pumps can connect directly to mash or lauter discharges, or be paired with custom hoppers to reduce manual handling and improve overall efficiency.

Silo Discharge Screws

Where gravity discharge is not possible, silo discharge or dosing screws provide a durable, high-throughput solution for removing spent grain. Designed for a wide range of material consistencies, these systems are commonly built in stainless steel with optional heat tracing and automated valves.

Centrifuges and Separation

Separators and centrifuges have long been used in brewing and distilling applications to clarify liquids and separate solids. Based on extensive industry experience, Alfa Laval separators are designed to meet the specific demands of brewery operations.

For distilling applications, centrifuge decanters can reduce total spent grain volume by removing additional liquid from slurry. This can simplify disposal and reduce hauling requirements.

Dust Collection

Dust control is an important consideration for any grain handling operation and is often required by local fire and safety authorities. Proper dust collection helps reduce combustible dust risks and supports safer working conditions.

Malt Handling provides dust collection systems designed to meet NFPA and NEC requirements for hazardous locations, including Class I, Group D and Class II, Groups F and G environments. Options range from centralized baghouse systems to portable collection units.

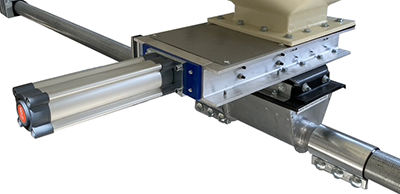

Knife Gate Valves

Knife gate valves provide reliable flow control for both dry and wet materials. They are commonly used in weighing, batching, and discharge applications and are available with options such as position sensors and actuated controls.

Automation and Integration

Automating grain handling equipment can improve consistency, reduce labor, and simplify operation. Our control systems tie storage, conveying, milling, and spent grain handling into a single interface tailored to your process.

From simple start-stop controls to fully integrated batching and weighing systems, we can design an automation approach that matches your needs without adding unnecessary complexity.